|

Voltage(V) |

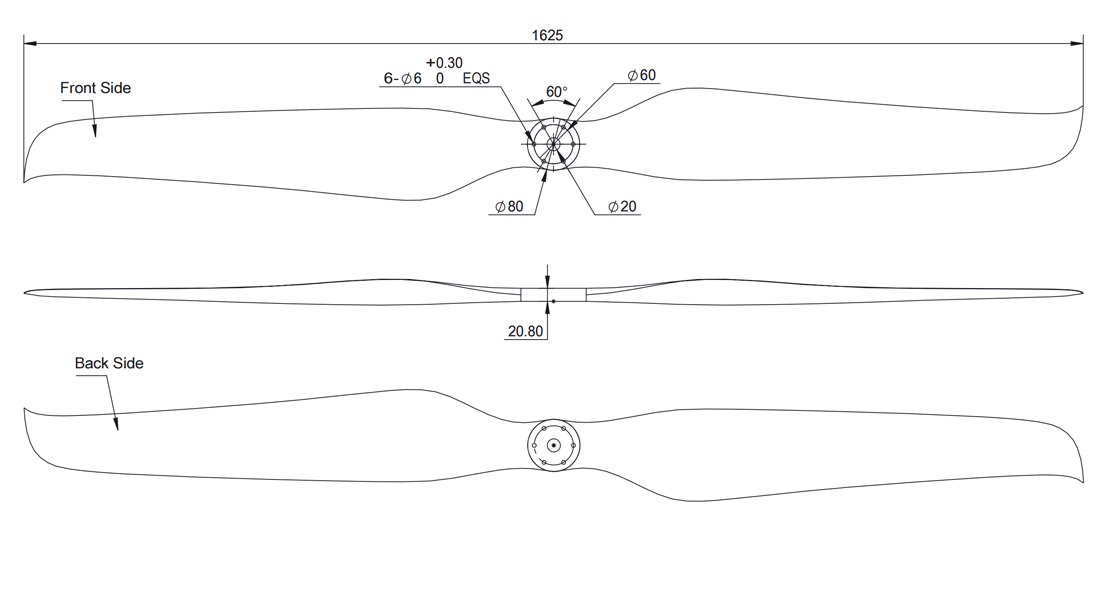

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

400V |

64x20" |

35% |

18099 |

4.9 |

1941.3 |

1153 |

9.3 |

10.50 |

92℃ |

|

37% |

20158 |

5.6 |

2231.4 |

1210 |

9.0 |

12.04 |

|||

|

39% |

24258 |

6.9 |

2766.3 |

1314 |

8.8 |

14.74 |

|||

|

42% |

27941 |

8.1 |

3233.5 |

1400 |

8.6 |

16.91 |

|||

|

45% |

33804 |

10.1 |

4026.0 |

1525 |

8.4 |

20.20 |

|||

|

48% |

39750 |

12.4 |

4963.7 |

1643 |

8.0 |

23.67 |

|||

|

51% |

46459 |

15.6 |

6242.0 |

1769 |

7.5 |

28.00 |

|||

|

54% |

51849 |

18.6 |

7450.9 |

1868 |

7.0 |

31.82 |

|||

|

57% |

56043 |

21.2 |

8497.8 |

1945 |

6.6 |

34.99 |

|||

|

60% |

62207 |

25.5 |

10183.0 |

2057 |

6.1 |

39.82 |

|||

|

63% |

65772 |

28.1 |

11222.9 |

2121 |

5.9 |

42.66 |

|||

|

66% |

69844 |

31.1 |

12455.2 |

2194 |

5.6 |

45.87 |

|||

|

69% |

73789 |

34.2 |

13682.1 |

2263 |

5.4 |

48.91 |

|||

|

72% |

77704 |

37.3 |

14920.9 |

2330 |

5.2 |

51.81 |

|||

|

75% |

82332 |

41.0 |

16401.0 |

2405 |

5.0 |

55.06 |

|||

|

78% |

85705 |

43.7 |

17485.7 |

2456 |

4.9 |

57.29 |

|||

|

81% |

89805 |

47.0 |

18809.1 |

2514 |

4.8 |

59.89 |

|||

|

84% |

93866 |

50.3 |

20130.2 |

2564 |

4.7 |

62.37 |

|||

|

87% |

98297 |

54.0 |

21596.4 |

2610 |

4.6 |

65.08 |

|||

|

90% |

99987 |

55.4 |

22166.9 |

2625 |

4.5 |

66.15 |

|||

|

100% |

104197 |

59.1 |

23633.3 |

2654 |

4.4 |

69.02 |

Integrated Propulsion System

System Design

- Software

- Adopts a rigorous modular design.

- Fully lsolated Design Architecture

- The hardware system implements a fully isolated design

- architecture with high-voltage power circuits,

- low-voltage signal circuits, and protective earthing(PE)

- ensuring reliable data transmission,

- stable equipment operation, and enhanced safety for

- both personneland systems.

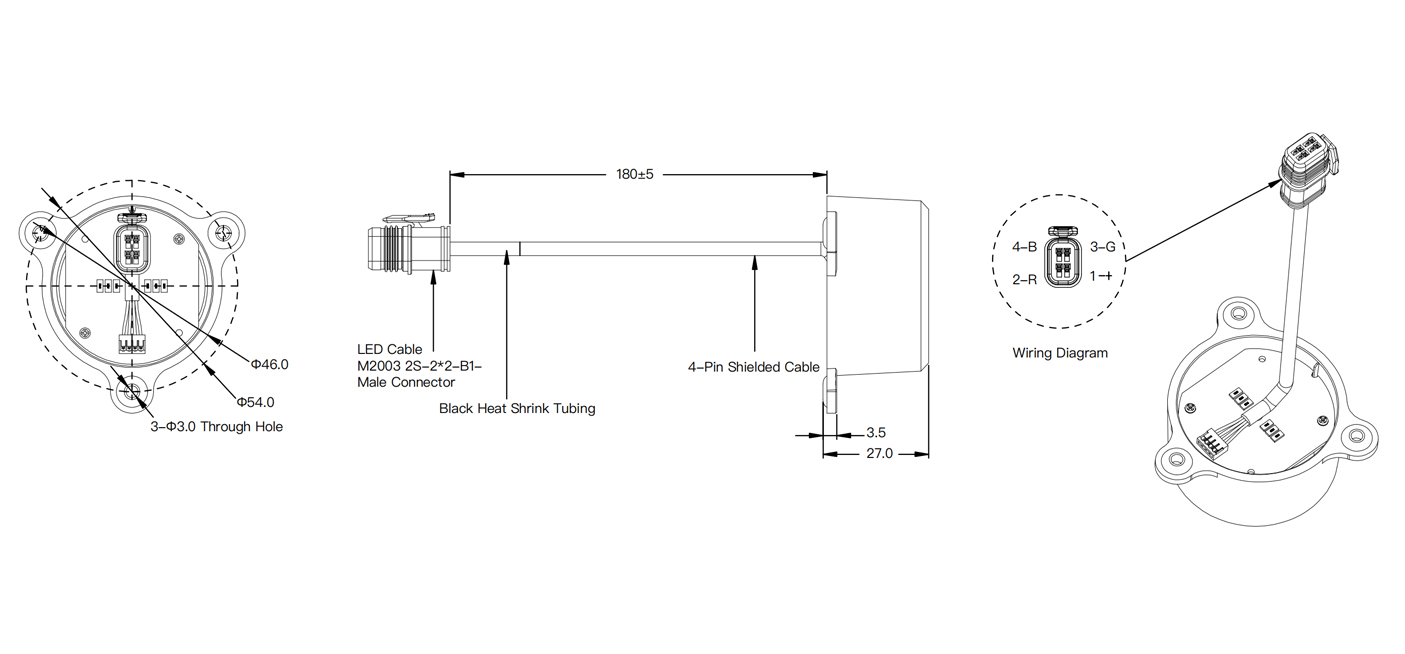

of Position Sensor

- Obtains PRM information in real time through dual channels

- to meet airworthiness certification requirements

- and flexibly respond to future regulatory requirements.

with High Reliability

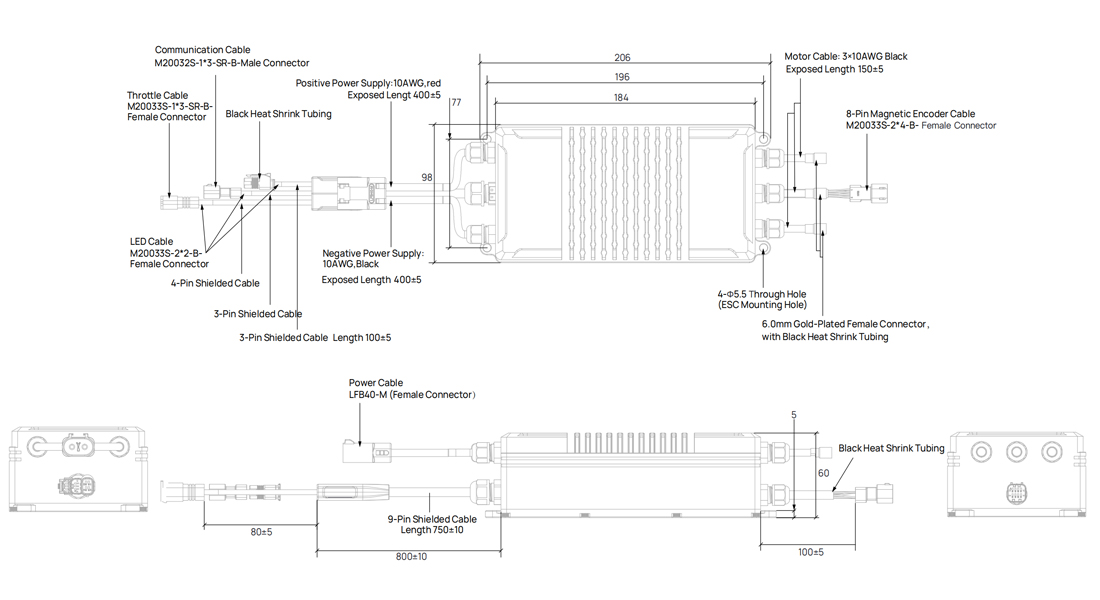

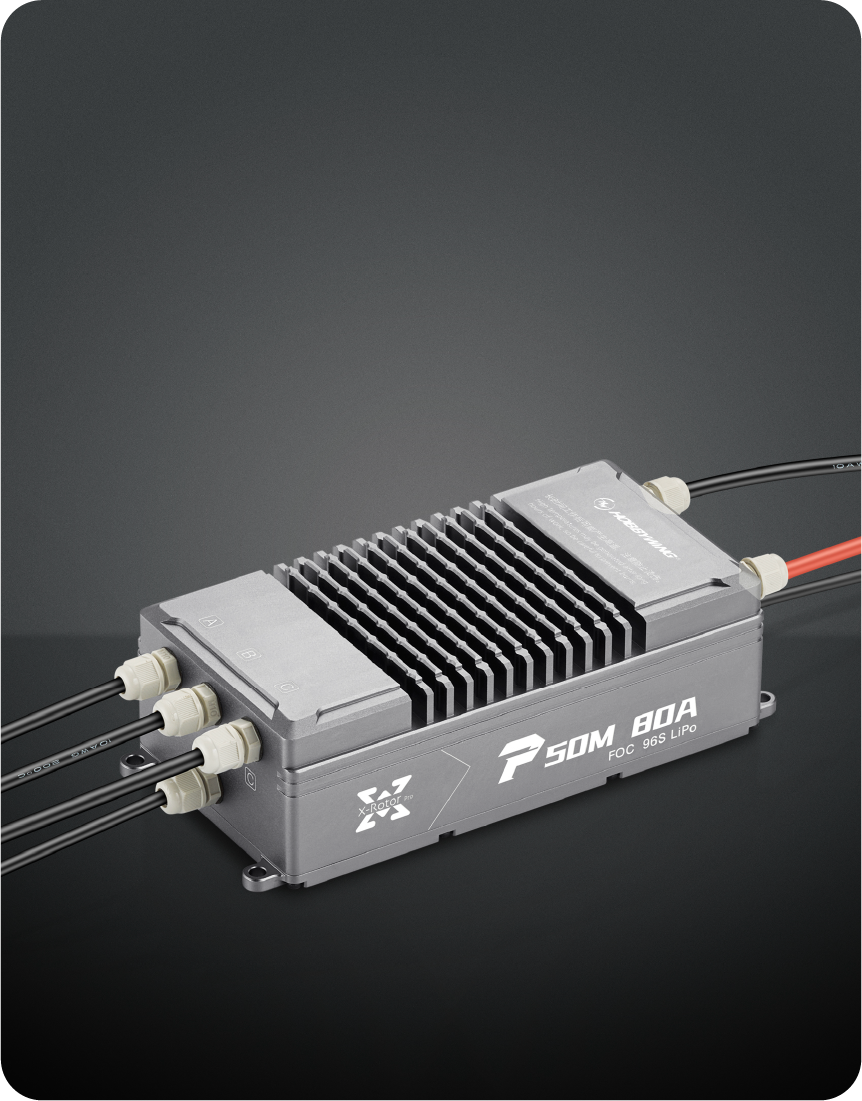

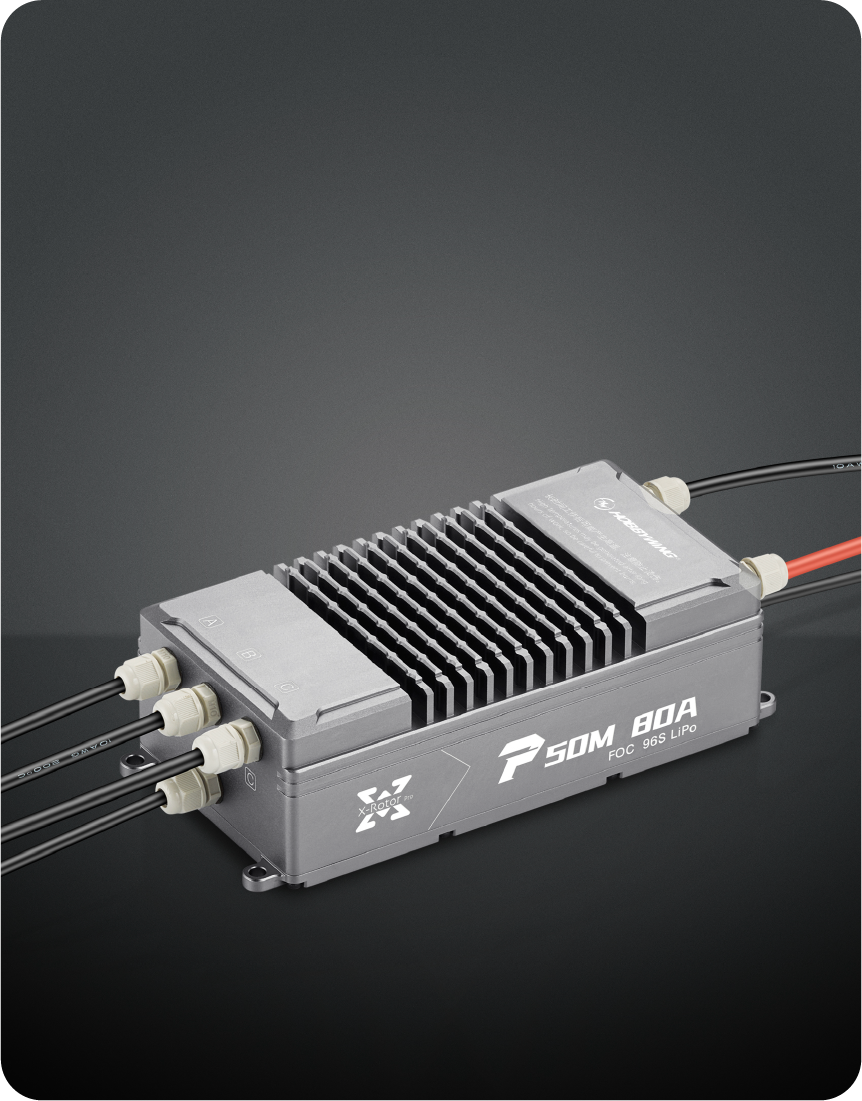

- ESC

- The electric speed controller (ESC)

- uses automotive-grade components

- with higher temperature resistance.

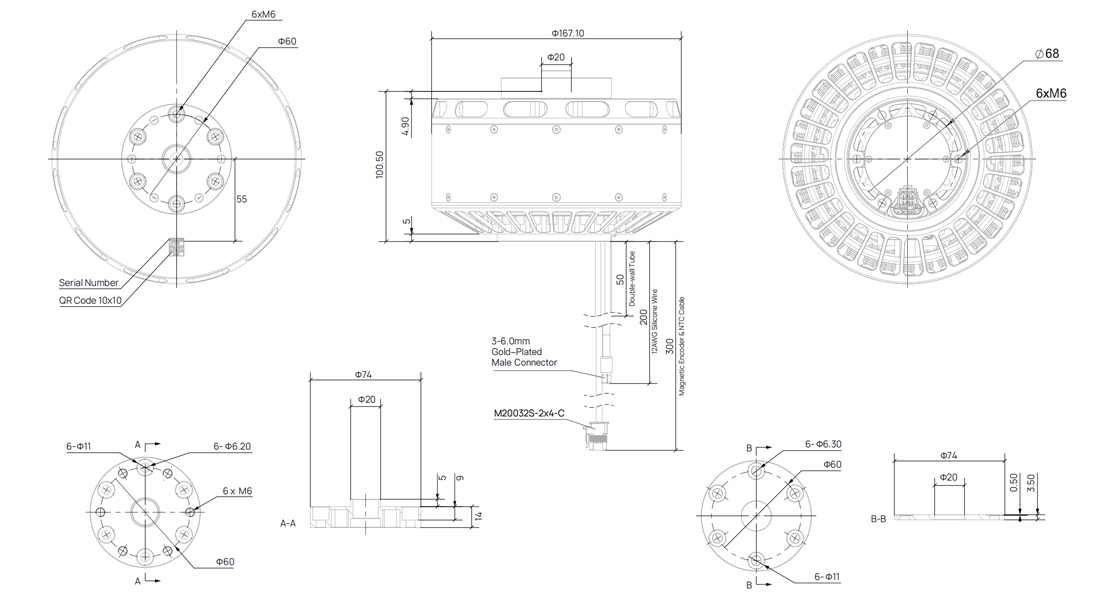

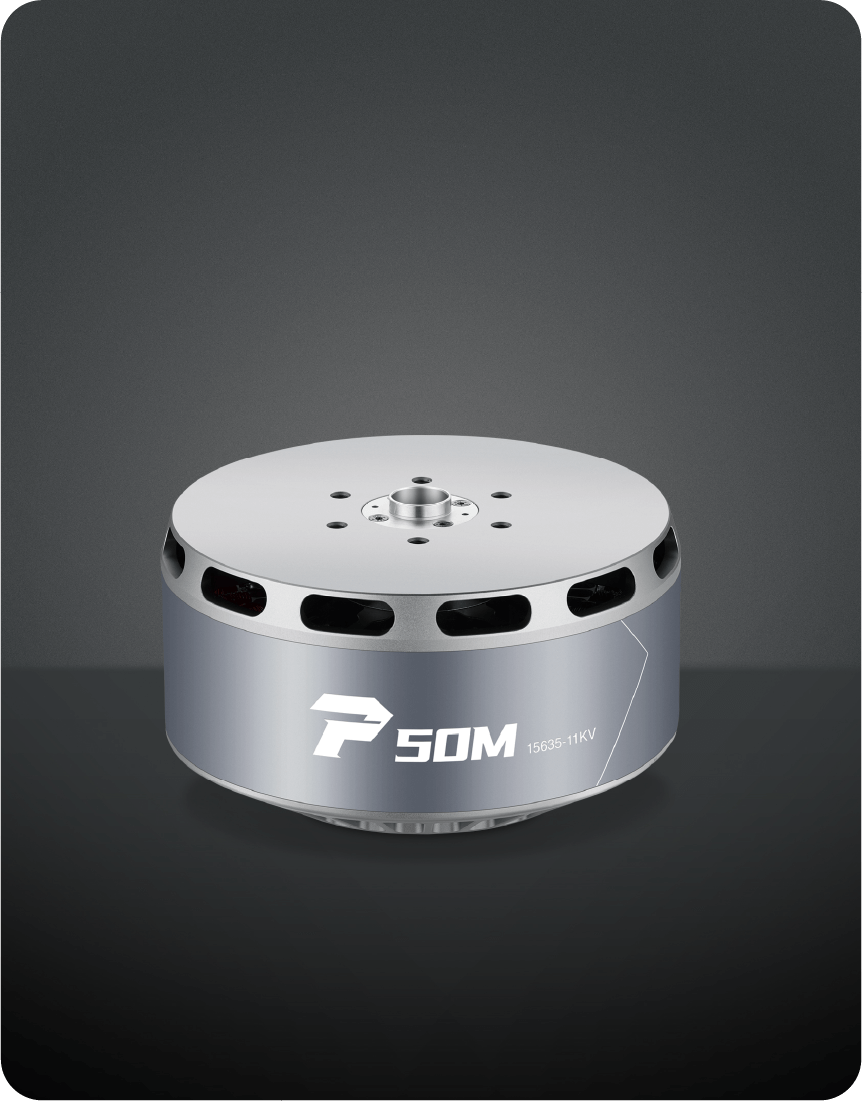

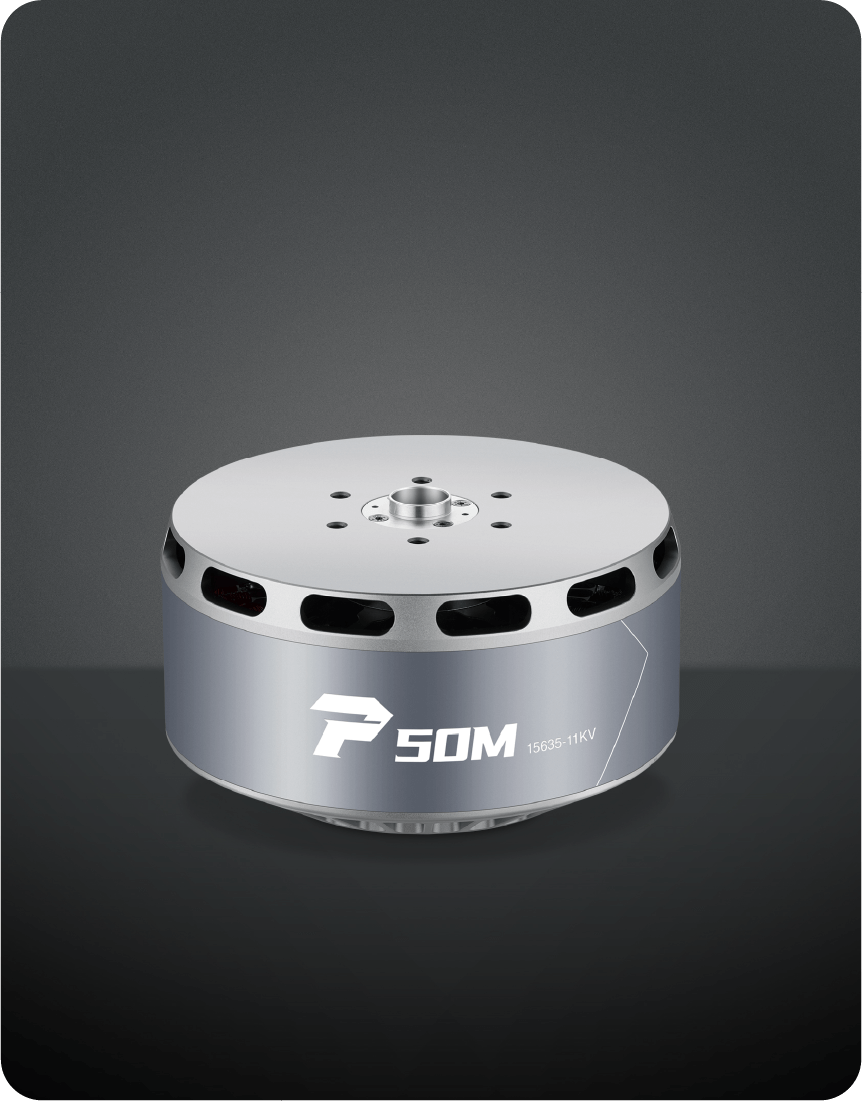

- Motor

- The motor is made of high temperature

- resistant material, combined with the

- dual design of knurl shaft and screws

- to avoid loosening.

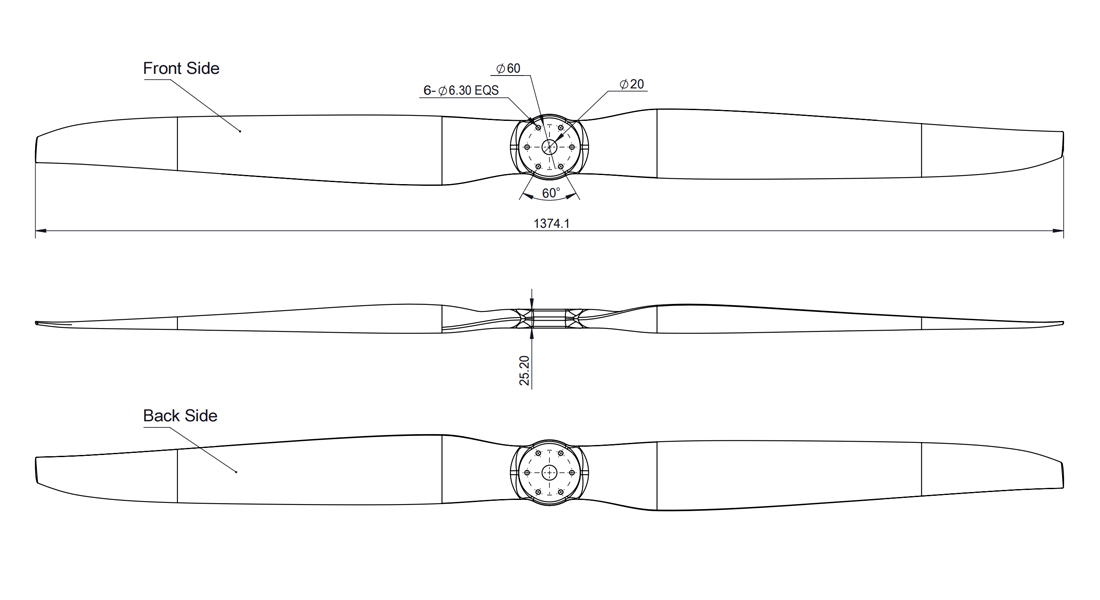

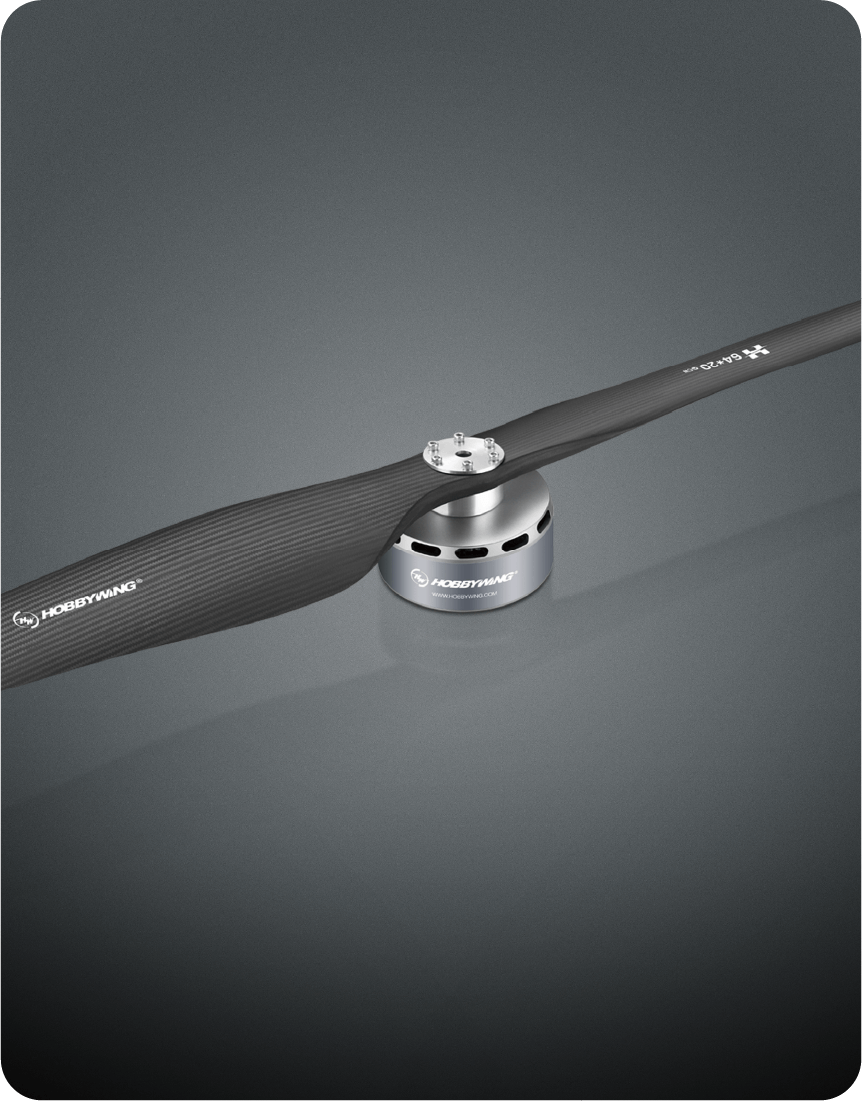

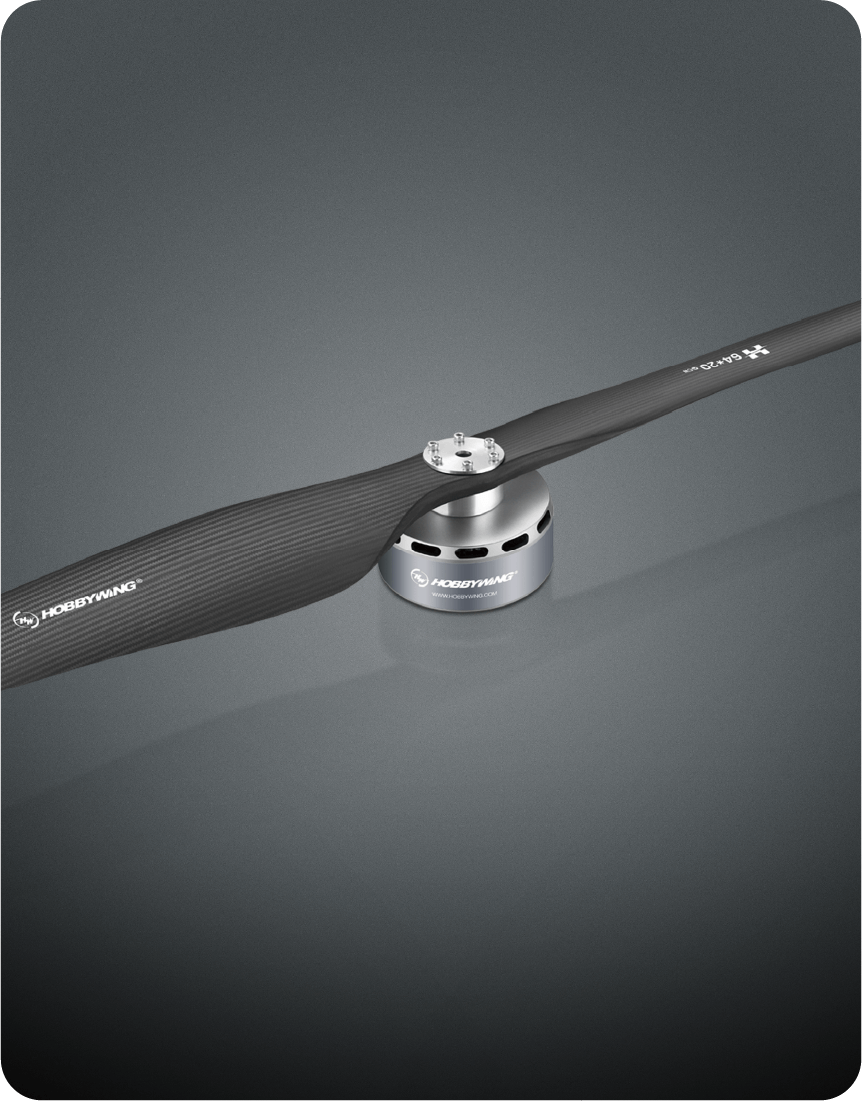

- Propeller

- The propeller adopts carbon

- fiber molding process.

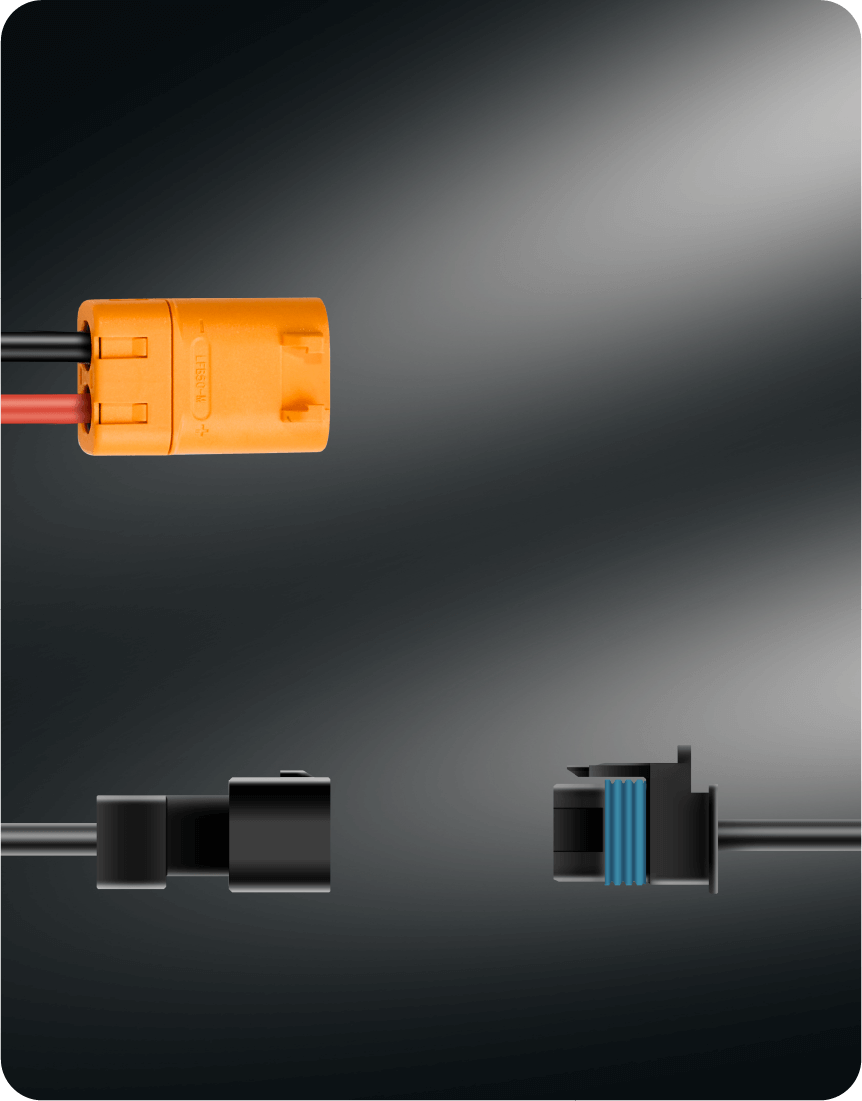

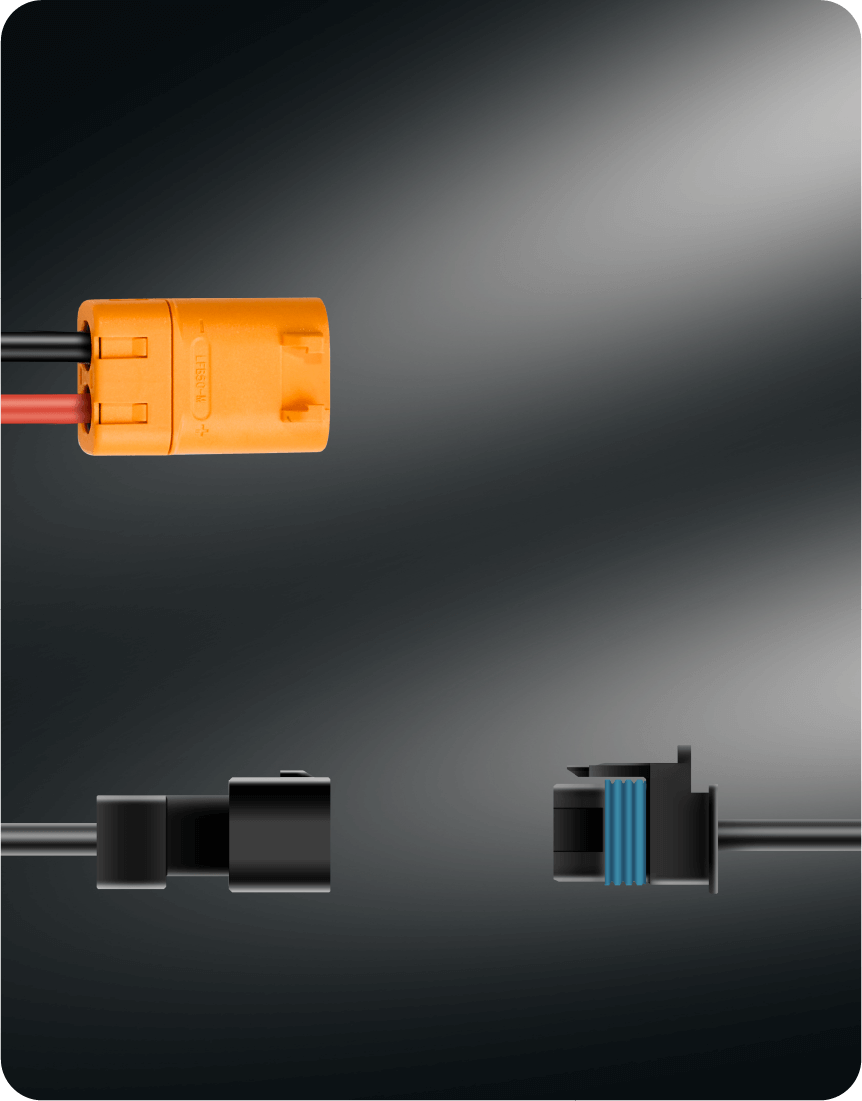

- Automotive-Grade

Connectors - Both high-voltage and low-voltage

- signal connectors are constructed with

- automotive-grade materials, featuring

- fool-proof design, prevention of poor

- contact, and vibration resistance.

- This ensures reliable system

- connectivity and extended service life.

Swipe left to view all

Swipe left to view allTriple Throttle Control Modes

Triple throttle control modes are as follows:

1

- PWM+CAN digital throttle

- is the default configuration

2

- PWM+RS485

- is optional

3

- CAN+RS485

- is optional

Enhanced Safety Assurance

A physical RPM sensor is used to directly obtain the RPM signal for motor control

enhance the reliability of the propulsion system

Without a physical RPM sensor, the RPM signal is obtained through software algorithms.

verified by over 1000 hours of continuous aging testing,

ensures maintenance-free operation throughout its entire lifecycle

developed and designed by HOBBYWING,

ensuring meticulous attention to every detail

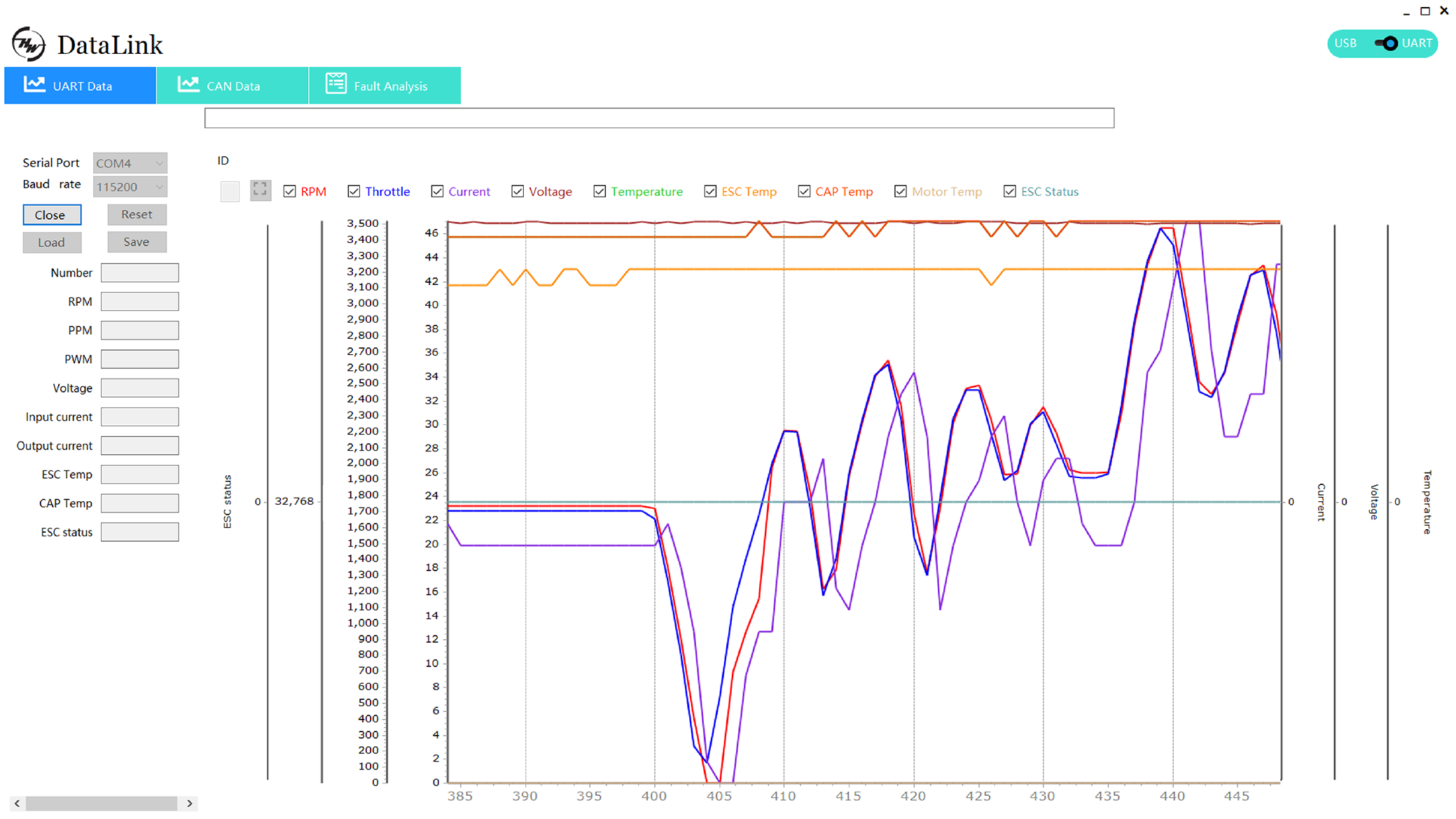

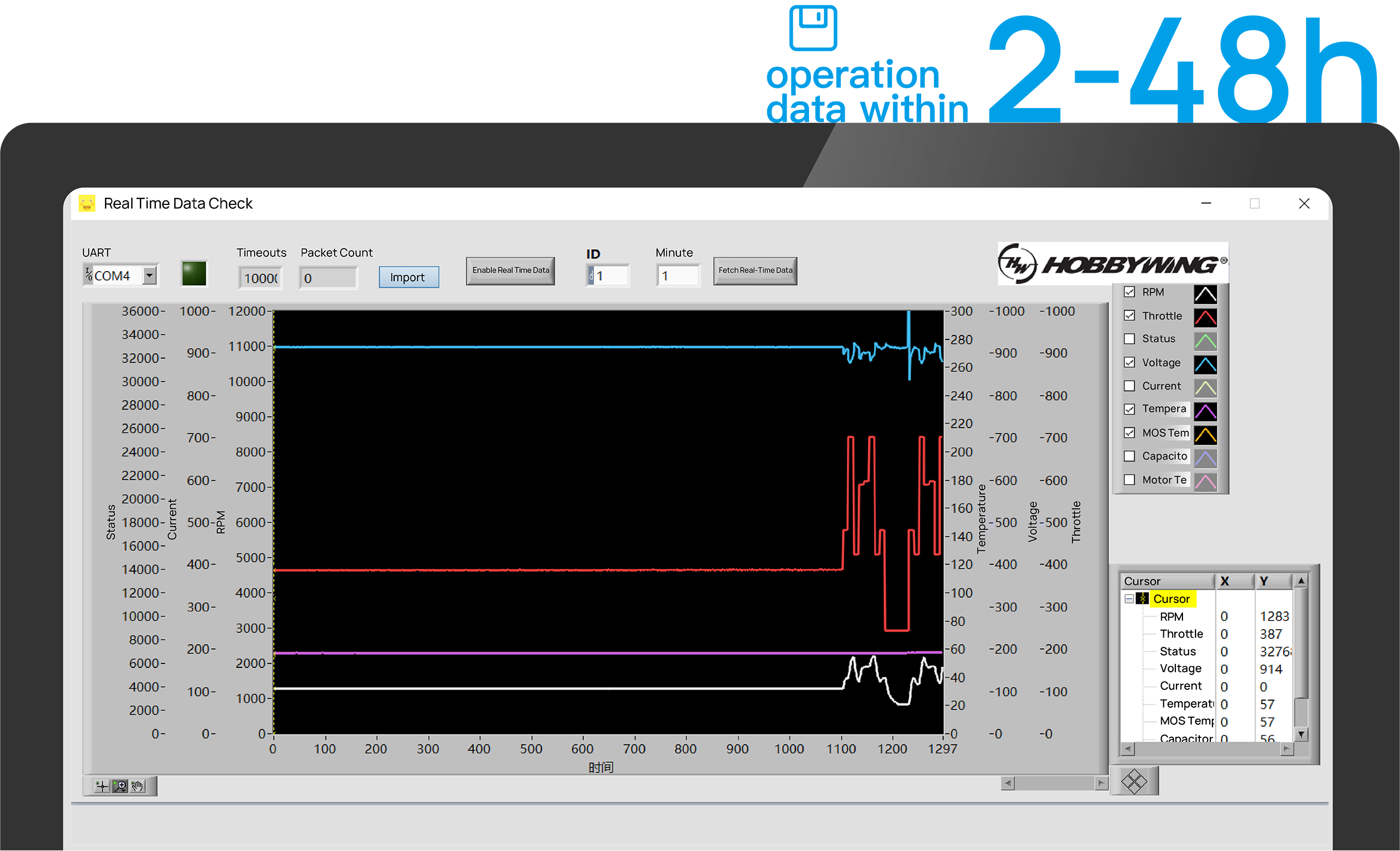

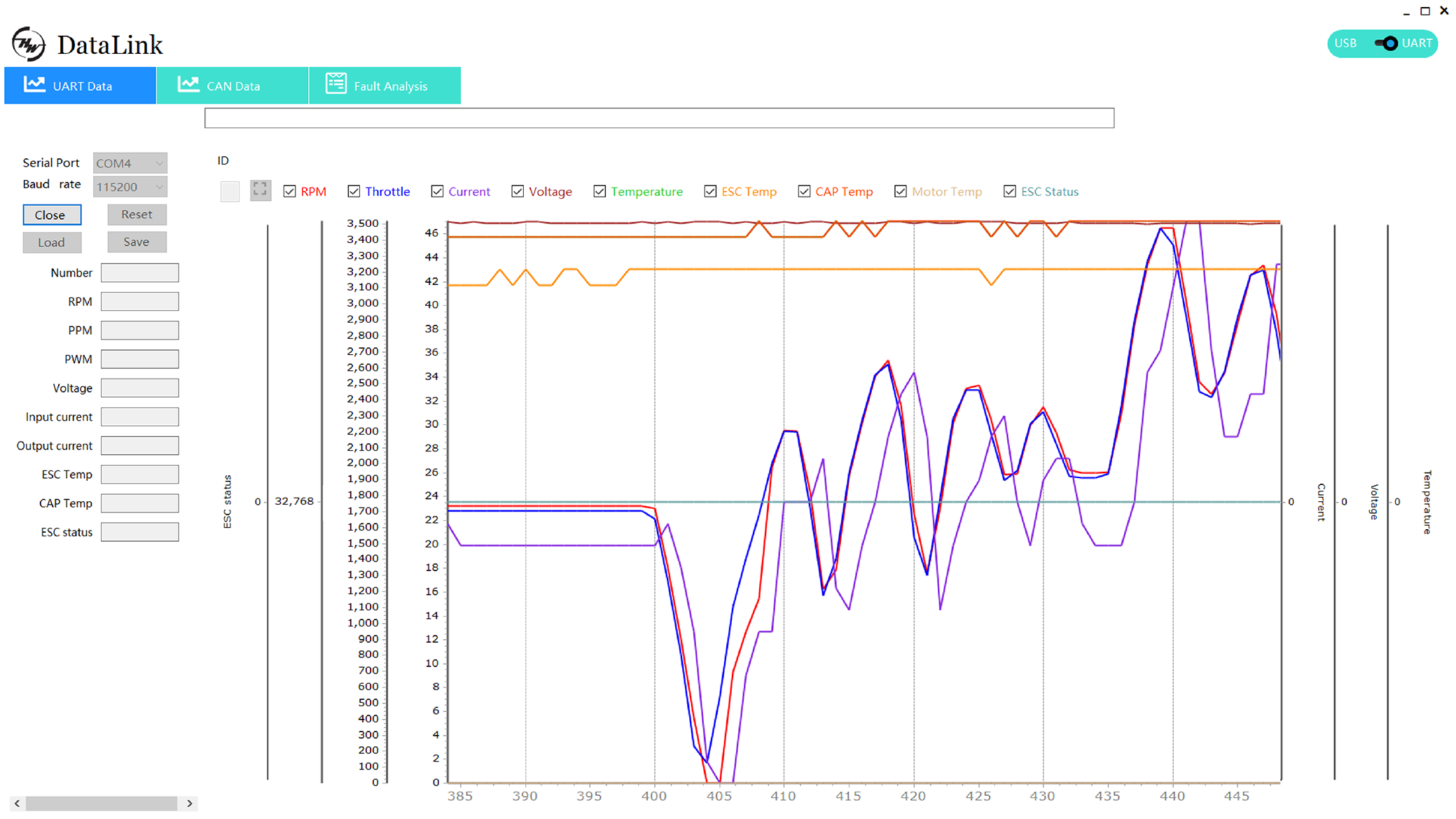

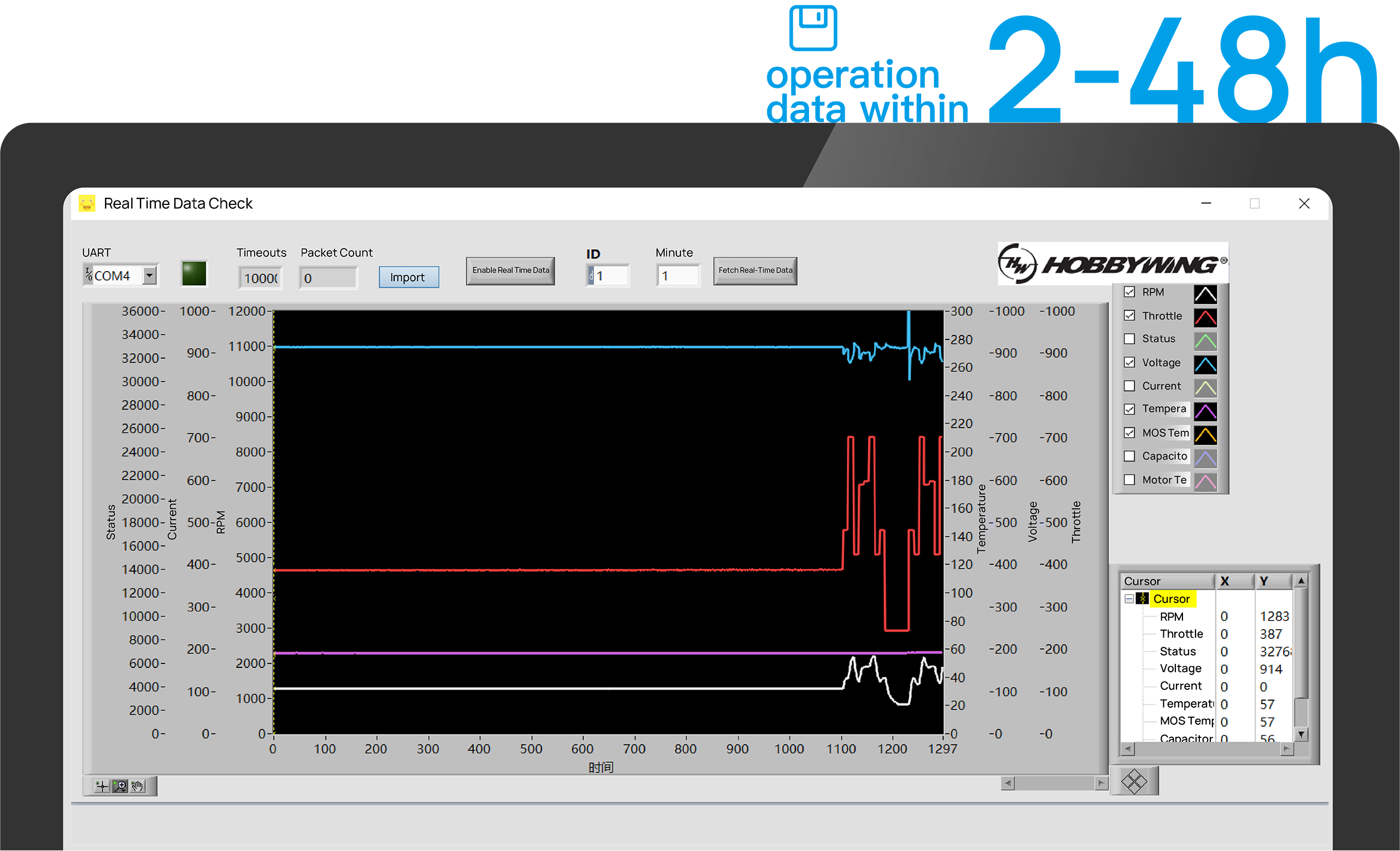

millisecond-level recording of real-time operational data,

enabling comprehensive traceability analysis

- The fault storage function records operational fault codes during operation,

- enabling precise root cause tracing.

- The system continuously records the drone's operational data for 2-48 hours,

- facilitating comprehensive post-flight data analysis.

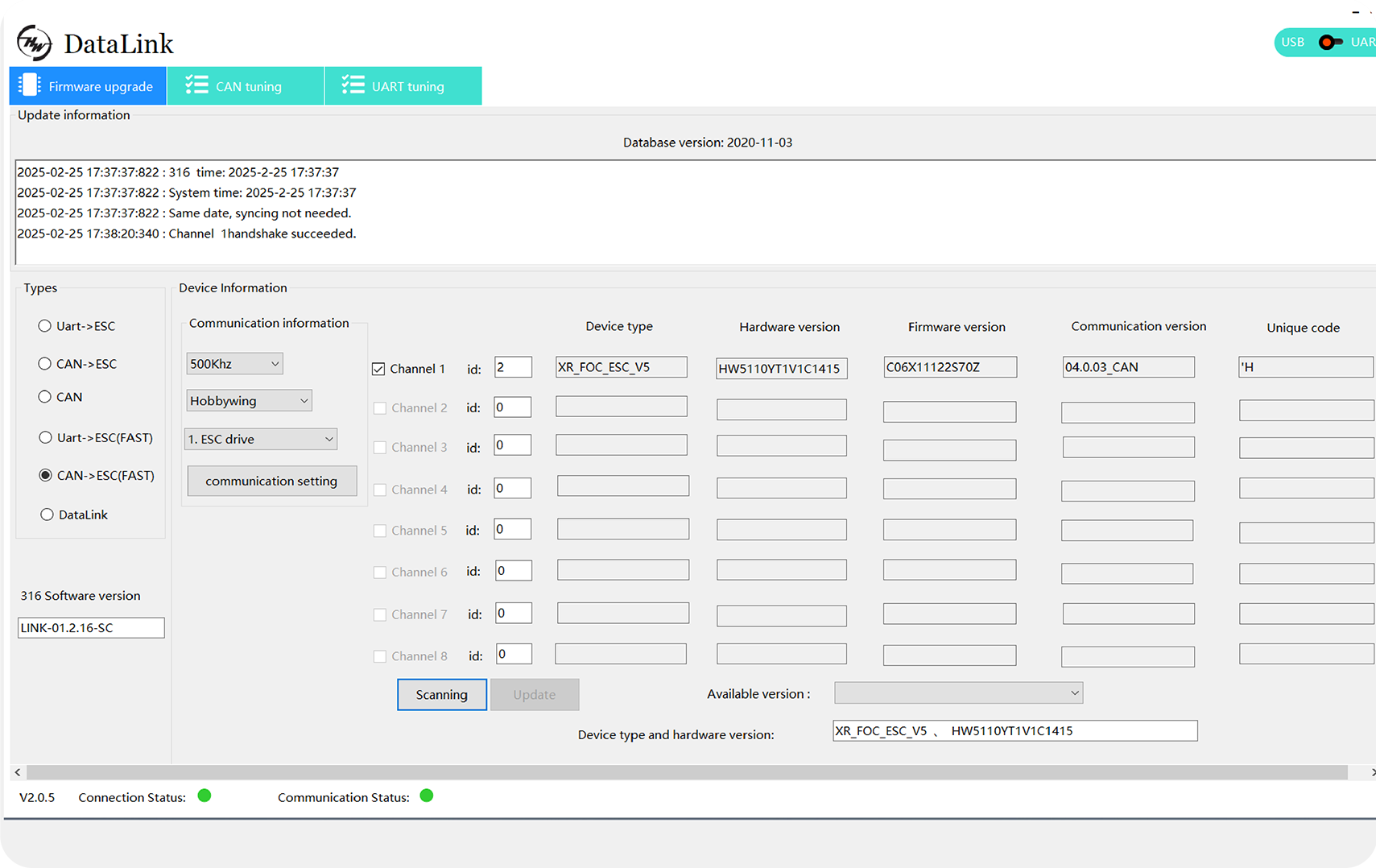

Firmware OTA Updates

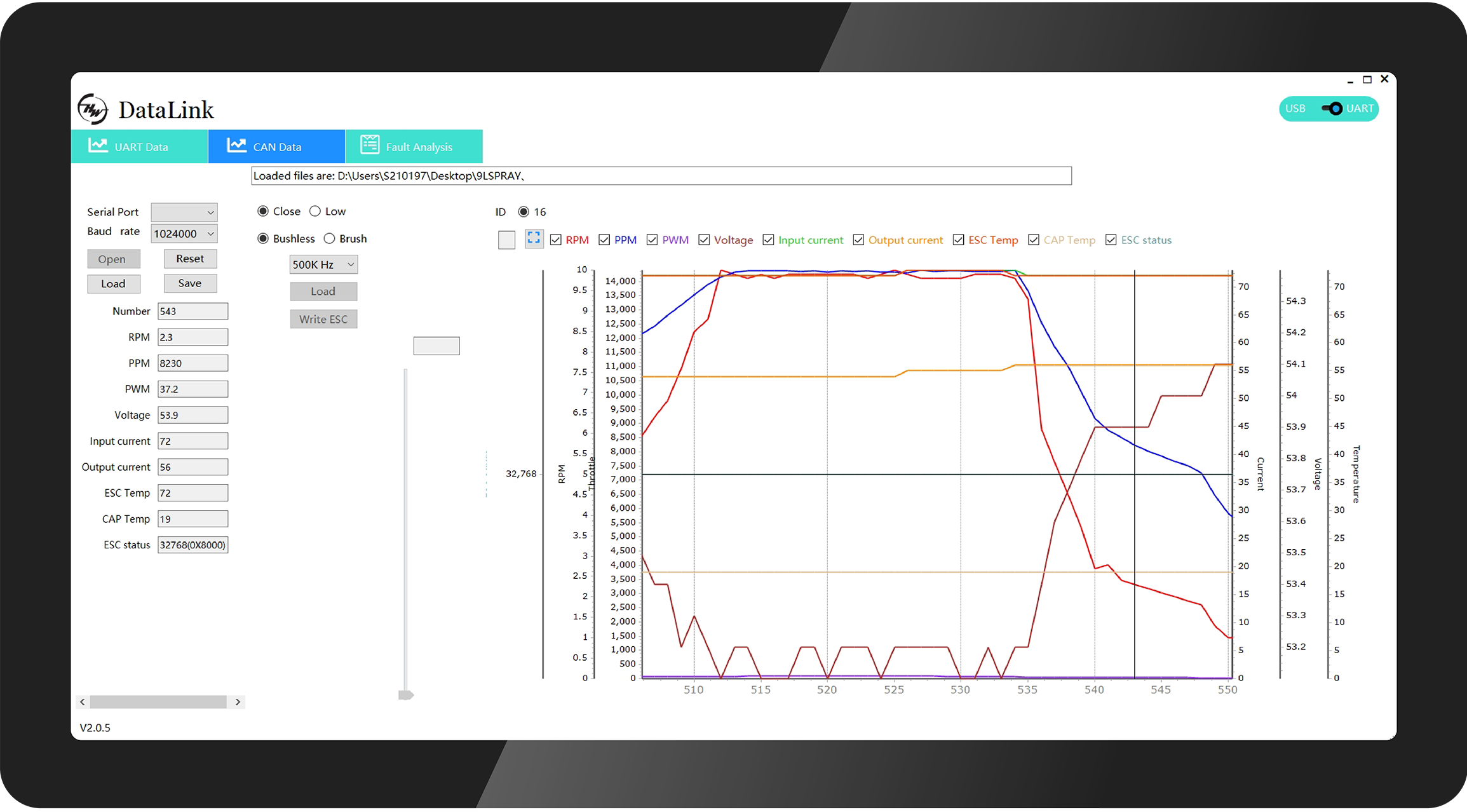

- With HOBBYWING’s proprietary host computer software (DataLink),

- users can adjust drive parameters, motor direction,

- and LED color (default green) effortlessly to optimize flight performance and upgrade the latest firmware.

Compatibility

ArduPilot open-source ecosystem, VK, Byaero and Jiyi, supports CAN communication,

and builds an intelligent flight ecosystem.

Feedback of Coil Temperature

-

Thank you for your interest in HOBBYWING propulsion systems! For customized solutions,

please provide your contact information and technical requirements,

and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

| Product Name |

|

||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||

| ESC specification |

|

||||||||||||||||||||||||||

| Motor specification |

|

||||||||||||||||||||||||||

| Propeller |

|

||||||||||||||||||||||||||

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

400V |

54x23" |

33% |

20087 |

6.4 |

2554.1 |

1501 |

7.9 |

12.91 |

90℃ |

|

35% |

23100 |

7.5 |

3003.4 |

1604 |

7.7 |

14.60 |

|||

|

37% |

26227 |

8.8 |

3538.8 |

1705 |

7.4 |

16.45 |

|||

|

39% |

29462 |

10.4 |

4150.7 |

1804 |

7.1 |

18.45 |

|||

|

42% |

34501 |

13.0 |

5190.7 |

1947 |

6.6 |

21.65 |

|||

|

45% |

39734 |

15.9 |

6348.7 |

2082 |

6.3 |

25.01 |

|||

|

48% |

45121 |

19.0 |

7598.3 |

2209 |

5.9 |

28.45 |

|||

|

51% |

50614 |

22.3 |

8921.6 |

2329 |

5.7 |

31.92 |

|||

|

54% |

56159 |

25.8 |

10310.3 |

2441 |

5.4 |

35.38 |

|||

|

57% |

61698 |

29.4 |

11762.9 |

2546 |

5.2 |

38.81 |

|||

|

60% |

67169 |

33.2 |

13280.1 |

2646 |

5.1 |

42.21 |

|||

|

63% |

72509 |

37.1 |

14859.2 |

2741 |

4.9 |

45.57 |

|||

|

66% |

77654 |

41.2 |

16488.2 |

2830 |

4.7 |

48.87 |

|||

|

69% |

82538 |

45.4 |

18142.8 |

2913 |

4.5 |

52.08 |

|||

|

72% |

87101 |

49.5 |

19786.2 |

2989 |

4.4 |

55.12 |

|||

|

75% |

91282 |

53.4 |

21372.3 |

3057 |

4.3 |

57.95 |

|||

|

78% |

95028 |

57.1 |

22850.9 |

3115 |

4.2 |

60.47 |

|||

|

81% |

98287 |

60.4 |

24174.2 |

3164 |

4.1 |

62.64 |

|||

|

84% |

101018 |

63.2 |

25301.6 |

3202 |

4.0 |

64.42 |

|||

|

87% |

103186 |

65.5 |

26203.5 |

3231 |

3.9 |

65.79 |

|||

|

90% |

104765 |

67.1 |

26861.8 |

3251 |

3.9 |

66.76 |

|||

|

100% |

106112 |

68.6 |

27422.8 |

3266 |

3.9 |

67.56 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

335V |

64x20" |

33% |

20811 |

6.7 |

2254.7 |

1242 |

9.2 |

14.83 |

98℃ |

|

35% |

23695 |

7.9 |

2631.3 |

1318 |

9.0 |

16.60 |

|||

|

37% |

26664 |

9.2 |

3090.0 |

1394 |

8.6 |

18.55 |

|||

|

39% |

29714 |

10.8 |

3617.8 |

1469 |

8.2 |

20.64 |

|||

|

42% |

34432 |

13.5 |

4512.5 |

1579 |

7.6 |

23.99 |

|||

|

45% |

39298 |

16.4 |

5500.5 |

1684 |

7.1 |

27.50 |

|||

|

48% |

44282 |

19.6 |

6557.8 |

1782 |

6.8 |

31.10 |

|||

|

51% |

49344 |

22.9 |

7672.6 |

1874 |

6.4 |

34.73 |

|||

|

54% |

54441 |

26.4 |

8844.6 |

1959 |

6.2 |

38.37 |

|||

|

57% |

59523 |

30.1 |

10080.0 |

2040 |

5.9 |

42.01 |

|||

|

60% |

64540 |

34.0 |

11385.6 |

2118 |

5.7 |

45.65 |

|||

|

63% |

69436 |

38.1 |

12761.4 |

2192 |

5.4 |

49.27 |

|||

|

66% |

74158 |

42.4 |

14195.0 |

2263 |

5.2 |

52.85 |

|||

|

69% |

78649 |

46.7 |

15659.4 |

2330 |

5.0 |

56.33 |

|||

|

72% |

82856 |

51.1 |

17113.7 |

2393 |

4.8 |

59.64 |

|||

|

75% |

86728 |

55.2 |

18509.0 |

2449 |

4.7 |

62.70 |

|||

|

78% |

90217 |

59.1 |

19795.3 |

2496 |

4.6 |

65.43 |

|||

|

81% |

93281 |

62.5 |

20929.1 |

2535 |

4.5 |

67.76 |

|||

|

84% |

95882 |

65.3 |

21879.9 |

2564 |

4.4 |

69.67 |

|||

|

87% |

97991 |

67.6 |

22632.2 |

2585 |

4.3 |

71.14 |

|||

|

90% |

99585 |

69.2 |

23184.1 |

2599 |

4.3 |

72.20 |

|||

|

100% |

101269 |

70.9 |

23745.4 |

2611 |

4.3 |

73.25 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

335V |

54x23" |

33% |

20372 |

7.5 |

2506.6 |

1504 |

8.1 |

12.82 |

94℃ |

|

35% |

23552 |

9.0 |

3005.9 |

1608 |

7.8 |

14.74 |

|||

|

37% |

26724 |

10.6 |

3561.2 |

1710 |

7.5 |

16.71 |

|||

|

39% |

29916 |

12.4 |

4168.0 |

1808 |

7.2 |

18.71 |

|||

|

42% |

34785 |

15.4 |

5169.0 |

1949 |

6.7 |

21.80 |

|||

|

45% |

39790 |

18.7 |

6274.1 |

2082 |

6.3 |

25.00 |

|||

|

48% |

44946 |

22.3 |

7479.0 |

2207 |

6.0 |

28.31 |

|||

|

51% |

50244 |

26.2 |

8780.2 |

2325 |

5.7 |

31.71 |

|||

|

54% |

55652 |

30.4 |

10174.2 |

2434 |

5.5 |

35.19 |

|||

|

57% |

61121 |

34.8 |

11656.7 |

2537 |

5.2 |

38.72 |

|||

|

60% |

66587 |

39.5 |

13220.2 |

2635 |

5.0 |

42.27 |

|||

|

63% |

71974 |

44.3 |

14850.7 |

2729 |

4.8 |

45.79 |

|||

|

66% |

77199 |

49.3 |

16525.2 |

2818 |

4.7 |

49.25 |

|||

|

69% |

82176 |

54.3 |

18209.0 |

2903 |

4.5 |

52.56 |

|||

|

72% |

86817 |

59.3 |

19857.4 |

2982 |

4.4 |

55.68 |

|||

|

75% |

91040 |

63.9 |

21418.3 |

3052 |

4.3 |

58.51 |

|||

|

78% |

94767 |

68.2 |

22838.8 |

3111 |

4.1 |

61.00 |

|||

|

81% |

97933 |

71.8 |

24070.8 |

3158 |

4.1 |

63.09 |

|||

|

84% |

100487 |

74.8 |

25076.7 |

3192 |

4.0 |

64.76 |

|||

|

87% |

102394 |

77.1 |

25832.4 |

3216 |

4.0 |

65.99 |

|||

|

90% |

103643 |

78.6 |

26328.1 |

3230 |

3.9 |

66.78 |

|||

|

100% |

104316 |

79.4 |

26595.4 |

3237 |

3.9 |

67.20 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.

Integrated Propulsion System

System Design

- Software

- Adopts a rigorous modular design.

- Fully lsolated Design Architecture

- The hardware system implements a fully isolated design

- architecture with high-voltage power circuits,

- low-voltage signal circuits, and protective earthing(PE)

- ensuring reliable data transmission,

- stable equipment operation, and enhanced safety for

- both personneland systems.

of Position Sensor

- Obtains PRM information in real time through dual channels

- to meet airworthiness certification requirements

- and flexibly respond to future regulatory requirements.

with High Reliability

- ESC

- The electric speed controller (ESC)

- uses automotive-grade components

- with higher temperature resistance.

- Motor

- The motor is made of high temperature

- resistant material, combined with the

- dual design of knurl shaft and screws

- to avoid loosening.

- Propeller

- The propeller adopts carbon

- fiber molding process.

- Automotive-Grade

Connectors - Both high-voltage and low-voltage

- signal connectors are constructed with

- automotive-grade materials, featuring

- fool-proof design, prevention of poor

- contact, and vibration resistance.

- This ensures reliable system

- connectivity and extended service life.

Swipe left to view all

Swipe left to view allTriple Throttle Control Modes

Triple throttle control modes are as follows:

1

- PWM+CAN digital throttle

- is the default configuration

2

- PWM+RS485

- is optional

3

- CAN+RS485

- is optional

Enhanced Safety Assurance

A physical RPM sensor is used to directly obtain the RPM signal for motor control

enhance the reliability of the propulsion system

Without a physical RPM sensor, the RPM signal is obtained through software algorithms.

verified by over 1000 hours of continuous aging testing,

ensures maintenance-free operation throughout its entire lifecycle

developed and designed by HOBBYWING,

ensuring meticulous attention to every detail

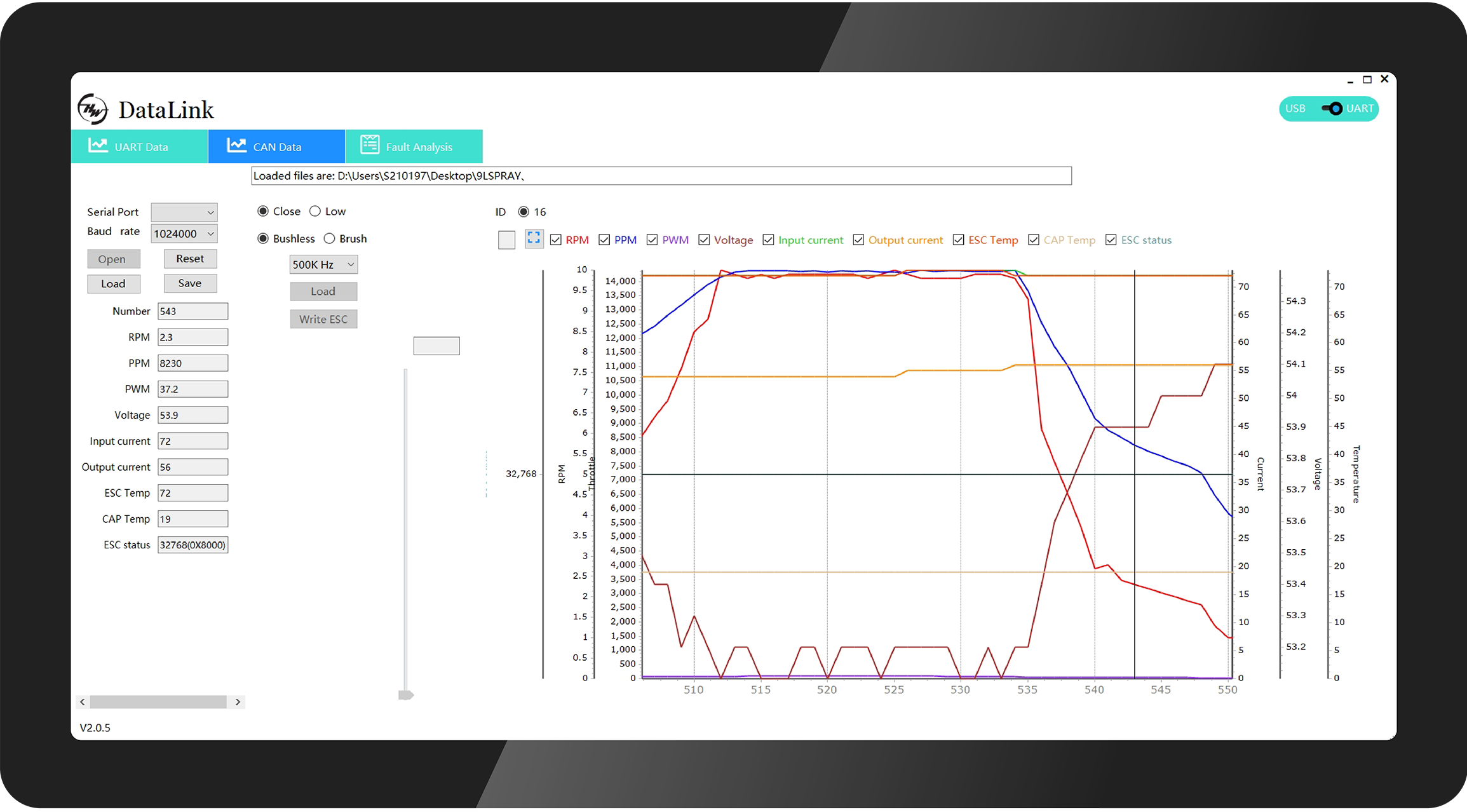

millisecond-level recording of real-time operational data,

enabling comprehensive traceability analysis

- The fault storage function records operational fault codes during operation,

- enabling precise root cause tracing.

- The system continuously records the drone's operational data for 2-48 hours,

- facilitating comprehensive post-flight data analysis.

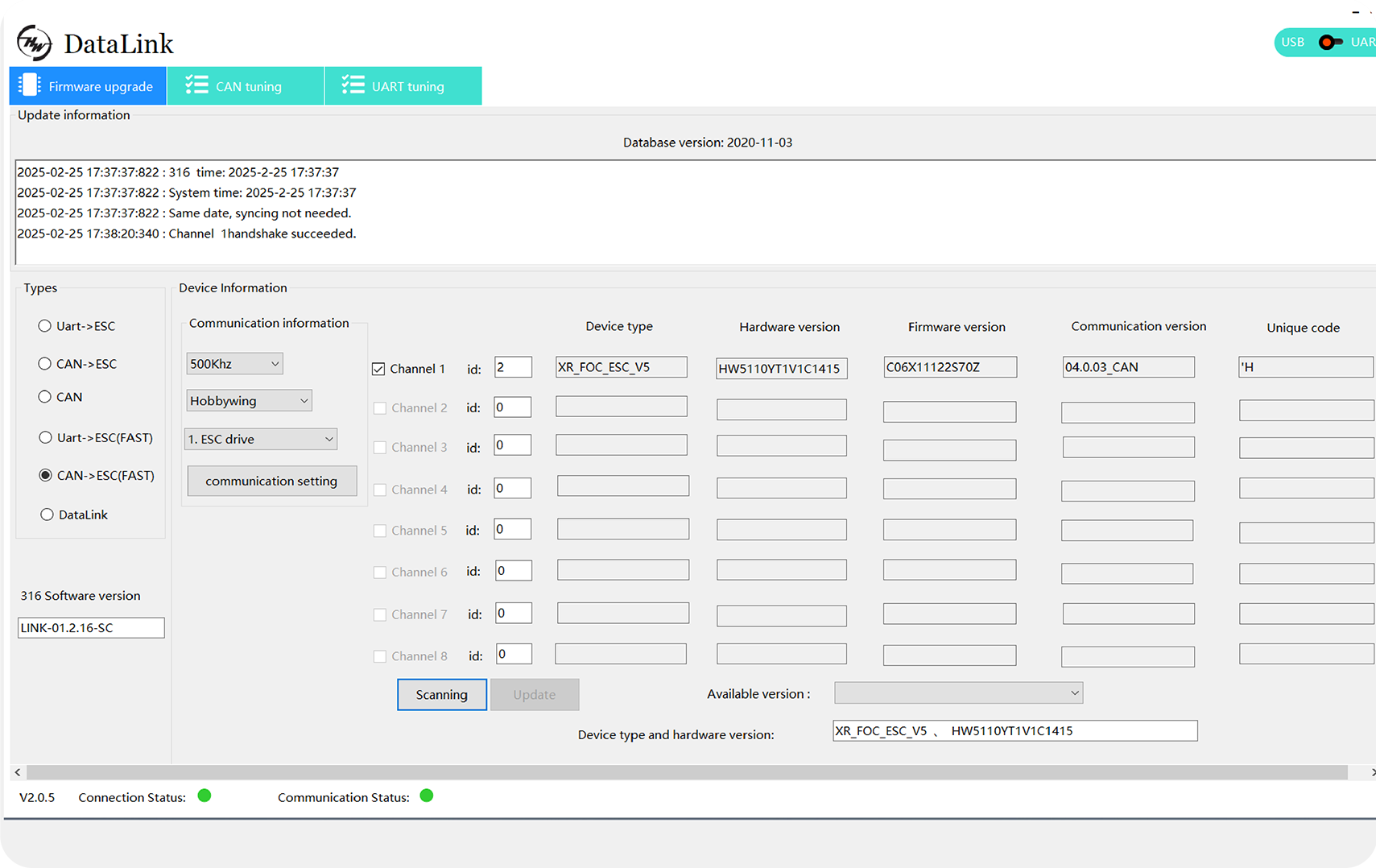

Firmware OTA Updates

- With HOBBYWING’s proprietary host computer software (DataLink),

- users can adjust drive parameters, motor direction,

- and LED color (default green) effortlessly to optimize flight performance and upgrade the latest firmware.

Compatibility

ArduPilot open-source ecosystem, VK, Byaero and Jiyi, supports CAN communication,

and builds an intelligent flight ecosystem.

Feedback of Coil Temperature

- Thank you for your interest in HOBBYWING propulsion systems! For customized solutions, please provide your contact information and technical requirements, and we will get in touch with you within 24 hours.

- Thanks for reaching out!We have received your message and will get back to you shortly.

- Best Regards,

HOBBYWING Team

| Product Name |

|

||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||

| ESC specification |

|

||||||||||||||||||||||||||

| Motor specification |

|

||||||||||||||||||||||||||

| Propeller |

|

||||||||||||||||||||||||||

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

400V |

64x20" |

35% |

18099 |

4.9 |

1941.3 |

1153 |

9.3 |

10.50 |

92℃ |

|

37% |

20158 |

5.6 |

2231.4 |

1210 |

9.0 |

12.04 |

|||

|

39% |

24258 |

6.9 |

2766.3 |

1314 |

8.8 |

14.74 |

|||

|

42% |

27941 |

8.1 |

3233.5 |

1400 |

8.6 |

16.91 |

|||

|

45% |

33804 |

10.1 |

4026.0 |

1525 |

8.4 |

20.20 |

|||

|

48% |

39750 |

12.4 |

4963.7 |

1643 |

8.0 |

23.67 |

|||

|

51% |

46459 |

15.6 |

6242.0 |

1769 |

7.5 |

28.00 |

|||

|

54% |

51849 |

18.6 |

7450.9 |

1868 |

7.0 |

31.82 |

|||

|

57% |

56043 |

21.2 |

8497.8 |

1945 |

6.6 |

34.99 |

|||

|

60% |

62207 |

25.5 |

10183.0 |

2057 |

6.1 |

39.82 |

|||

|

63% |

65772 |

28.1 |

11222.9 |

2121 |

5.9 |

42.66 |

|||

|

66% |

69844 |

31.1 |

12455.2 |

2194 |

5.6 |

45.87 |

|||

|

69% |

73789 |

34.2 |

13682.1 |

2263 |

5.4 |

48.91 |

|||

|

72% |

77704 |

37.3 |

14920.9 |

2330 |

5.2 |

51.81 |

|||

|

75% |

82332 |

41.0 |

16401.0 |

2405 |

5.0 |

55.06 |

|||

|

78% |

85705 |

43.7 |

17485.7 |

2456 |

4.9 |

57.29 |

|||

|

81% |

89805 |

47.0 |

18809.1 |

2514 |

4.8 |

59.89 |

|||

|

84% |

93866 |

50.3 |

20130.2 |

2564 |

4.7 |

62.37 |

|||

|

87% |

98297 |

54.0 |

21596.4 |

2610 |

4.6 |

65.08 |

|||

|

90% |

99987 |

55.4 |

22166.9 |

2625 |

4.5 |

66.15 |

|||

|

100% |

104197 |

59.1 |

23633.3 |

2654 |

4.4 |

69.02 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

400V |

54x23" |

33% |

20087 |

6.4 |

2554.1 |

1501 |

7.9 |

12.91 |

90℃ |

|

35% |

23100 |

7.5 |

3003.4 |

1604 |

7.7 |

14.60 |

|||

|

37% |

26227 |

8.8 |

3538.8 |

1705 |

7.4 |

16.45 |

|||

|

39% |

29462 |

10.4 |

4150.7 |

1804 |

7.1 |

18.45 |

|||

|

42% |

34501 |

13.0 |

5190.7 |

1947 |

6.6 |

21.65 |

|||

|

45% |

39734 |

15.9 |

6348.7 |

2082 |

6.3 |

25.01 |

|||

|

48% |

45121 |

19.0 |

7598.3 |

2209 |

5.9 |

28.45 |

|||

|

51% |

50614 |

22.3 |

8921.6 |

2329 |

5.7 |

31.92 |

|||

|

54% |

56159 |

25.8 |

10310.3 |

2441 |

5.4 |

35.38 |

|||

|

57% |

61698 |

29.4 |

11762.9 |

2546 |

5.2 |

38.81 |

|||

|

60% |

67169 |

33.2 |

13280.1 |

2646 |

5.1 |

42.21 |

|||

|

63% |

72509 |

37.1 |

14859.2 |

2741 |

4.9 |

45.57 |

|||

|

66% |

77654 |

41.2 |

16488.2 |

2830 |

4.7 |

48.87 |

|||

|

69% |

82538 |

45.4 |

18142.8 |

2913 |

4.5 |

52.08 |

|||

|

72% |

87101 |

49.5 |

19786.2 |

2989 |

4.4 |

55.12 |

|||

|

75% |

91282 |

53.4 |

21372.3 |

3057 |

4.3 |

57.95 |

|||

|

78% |

95028 |

57.1 |

22850.9 |

3115 |

4.2 |

60.47 |

|||

|

81% |

98287 |

60.4 |

24174.2 |

3164 |

4.1 |

62.64 |

|||

|

84% |

101018 |

63.2 |

25301.6 |

3202 |

4.0 |

64.42 |

|||

|

87% |

103186 |

65.5 |

26203.5 |

3231 |

3.9 |

65.79 |

|||

|

90% |

104765 |

67.1 |

26861.8 |

3251 |

3.9 |

66.76 |

|||

|

100% |

106112 |

68.6 |

27422.8 |

3266 |

3.9 |

67.56 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

335V |

64x20" |

33% |

20811 |

6.7 |

2254.7 |

1242 |

9.2 |

14.83 |

98℃ |

|

35% |

23695 |

7.9 |

2631.3 |

1318 |

9.0 |

16.60 |

|||

|

37% |

26664 |

9.2 |

3090.0 |

1394 |

8.6 |

18.55 |

|||

|

39% |

29714 |

10.8 |

3617.8 |

1469 |

8.2 |

20.64 |

|||

|

42% |

34432 |

13.5 |

4512.5 |

1579 |

7.6 |

23.99 |

|||

|

45% |

39298 |

16.4 |

5500.5 |

1684 |

7.1 |

27.50 |

|||

|

48% |

44282 |

19.6 |

6557.8 |

1782 |

6.8 |

31.10 |

|||

|

51% |

49344 |

22.9 |

7672.6 |

1874 |

6.4 |

34.73 |

|||

|

54% |

54441 |

26.4 |

8844.6 |

1959 |

6.2 |

38.37 |

|||

|

57% |

59523 |

30.1 |

10080.0 |

2040 |

5.9 |

42.01 |

|||

|

60% |

64540 |

34.0 |

11385.6 |

2118 |

5.7 |

45.65 |

|||

|

63% |

69436 |

38.1 |

12761.4 |

2192 |

5.4 |

49.27 |

|||

|

66% |

74158 |

42.4 |

14195.0 |

2263 |

5.2 |

52.85 |

|||

|

69% |

78649 |

46.7 |

15659.4 |

2330 |

5.0 |

56.33 |

|||

|

72% |

82856 |

51.1 |

17113.7 |

2393 |

4.8 |

59.64 |

|||

|

75% |

86728 |

55.2 |

18509.0 |

2449 |

4.7 |

62.70 |

|||

|

78% |

90217 |

59.1 |

19795.3 |

2496 |

4.6 |

65.43 |

|||

|

81% |

93281 |

62.5 |

20929.1 |

2535 |

4.5 |

67.76 |

|||

|

84% |

95882 |

65.3 |

21879.9 |

2564 |

4.4 |

69.67 |

|||

|

87% |

97991 |

67.6 |

22632.2 |

2585 |

4.3 |

71.14 |

|||

|

90% |

99585 |

69.2 |

23184.1 |

2599 |

4.3 |

72.20 |

|||

|

100% |

101269 |

70.9 |

23745.4 |

2611 |

4.3 |

73.25 |

|

Voltage(V) |

Propeller |

Throttle(%) |

Thrust(g) |

Current(A) |

Power(W) |

Speed(RPM) |

Efficiency(g/W) |

Torque(N-m) |

Temperature℃ |

|---|---|---|---|---|---|---|---|---|---|

|

335V |

54x23" |

33% |

20372 |

7.5 |

2506.6 |

1504 |

8.1 |

12.82 |

94℃ |

|

35% |

23552 |

9.0 |

3005.9 |

1608 |

7.8 |

14.74 |

|||

|

37% |

26724 |

10.6 |

3561.2 |

1710 |

7.5 |

16.71 |

|||

|

39% |

29916 |

12.4 |

4168.0 |

1808 |

7.2 |

18.71 |

|||

|

42% |

34785 |

15.4 |

5169.0 |

1949 |

6.7 |

21.80 |

|||

|

45% |

39790 |

18.7 |

6274.1 |

2082 |

6.3 |

25.00 |

|||

|

48% |

44946 |

22.3 |

7479.0 |

2207 |

6.0 |

28.31 |

|||

|

51% |

50244 |

26.2 |

8780.2 |

2325 |

5.7 |

31.71 |

|||

|

54% |

55652 |

30.4 |

10174.2 |

2434 |

5.5 |

35.19 |

|||

|

57% |

61121 |

34.8 |

11656.7 |

2537 |

5.2 |

38.72 |

|||

|

60% |

66587 |

39.5 |

13220.2 |

2635 |

5.0 |

42.27 |

|||

|

63% |

71974 |

44.3 |

14850.7 |

2729 |

4.8 |

45.79 |

|||

|

66% |

77199 |

49.3 |

16525.2 |

2818 |

4.7 |

49.25 |

|||

|

69% |

82176 |

54.3 |

18209.0 |

2903 |

4.5 |

52.56 |

|||

|

72% |

86817 |

59.3 |

19857.4 |

2982 |

4.4 |

55.68 |

|||

|

75% |

91040 |

63.9 |

21418.3 |

3052 |

4.3 |

58.51 |

|||

|

78% |

94767 |

68.2 |

22838.8 |

3111 |

4.1 |

61.00 |

|||

|

81% |

97933 |

71.8 |

24070.8 |

3158 |

4.1 |

63.09 |

|||

|

84% |

100487 |

74.8 |

25076.7 |

3192 |

4.0 |

64.76 |

|||

|

87% |

102394 |

77.1 |

25832.4 |

3216 |

4.0 |

65.99 |

|||

|

90% |

103643 |

78.6 |

26328.1 |

3230 |

3.9 |

66.78 |

|||

|

100% |

104316 |

79.4 |

26595.4 |

3237 |

3.9 |

67.20 |

Support

Manuals & Documents

Disclaimer

The purpose of this website is only to introduce you to the basic situation of HOBBYWING company and product information. Unless otherwise stated, all information provided on this website should not be regarded as an offer or acceptance, and this website will not assume any binding obligations to you as a result of the provision of information. For all your requests, HOBBYWING reserves the full right to decide whether to commit or not.

This Website and its contents are provided for your convenience on an "as is" basis and your use of this Website is at your sole risk. HOBBYWING does not guarantee that this website will be uninterrupted or error-free, and reserves the right to amend this website or withdraw access to this Website at any time. We make no warranties, express or implied, as to the content, existence, accuracy or reliability of this Website, including, but not limited to, warranties of title, non-infringement or implied warranties of merchantability or fitness for a particular purpose or use.

HOBBYWING shall not be liable for any direct, indirect, incidental, special or consequential damages, loss of profits or business interruption caused by the use or inability to use the services provided by the Website, even if HOBBYWING has been advised of the possibility of similar losses. The exclusions and limitations of the warranty liability of HOBBYWING shall be effective to the extent permitted by applicable law.

HOBBYWING shall not be liable for any damage or loss to your computer system or any other software, hardware, IT system or property caused by viruses or other destructive programs caused by accessing, viewing and using this website or downloading any content from this Website (including but not limited to 2D model files, 3D model files).

HOBBYWING shall not be liable for any direct or indirect damage or loss caused by any third party using illegal means to access the website to obtain the relevant passwords, information and content.

If you or your company is located in the United States or Canada, you need to fill out this disclaimer confirmation letter online and submit it successfully before you can download the relevant materials you are interested in. The link address you fill in online is https://www.hobbywingdirect.com/pages/digital-file-release-form

If you do not agree with this disclaimer, please do not continue to this page. If you continue to access, browse and use this interface, you have read, understood and agreed to be bound by this statement and comply with all applicable laws and regulations.

HOBBYWING reserves the right to correct, modify and update this statement at any time.